CryoDoser FleX®

The first doser with the ability to serve every dosing application within one unit. From the slowest production lines to the fastest, the CryoDoser FleX is the only liquid nitrogen doser you need.

±2% Repeatability

Industry Leading Accuracy

Two Premium Controller Options

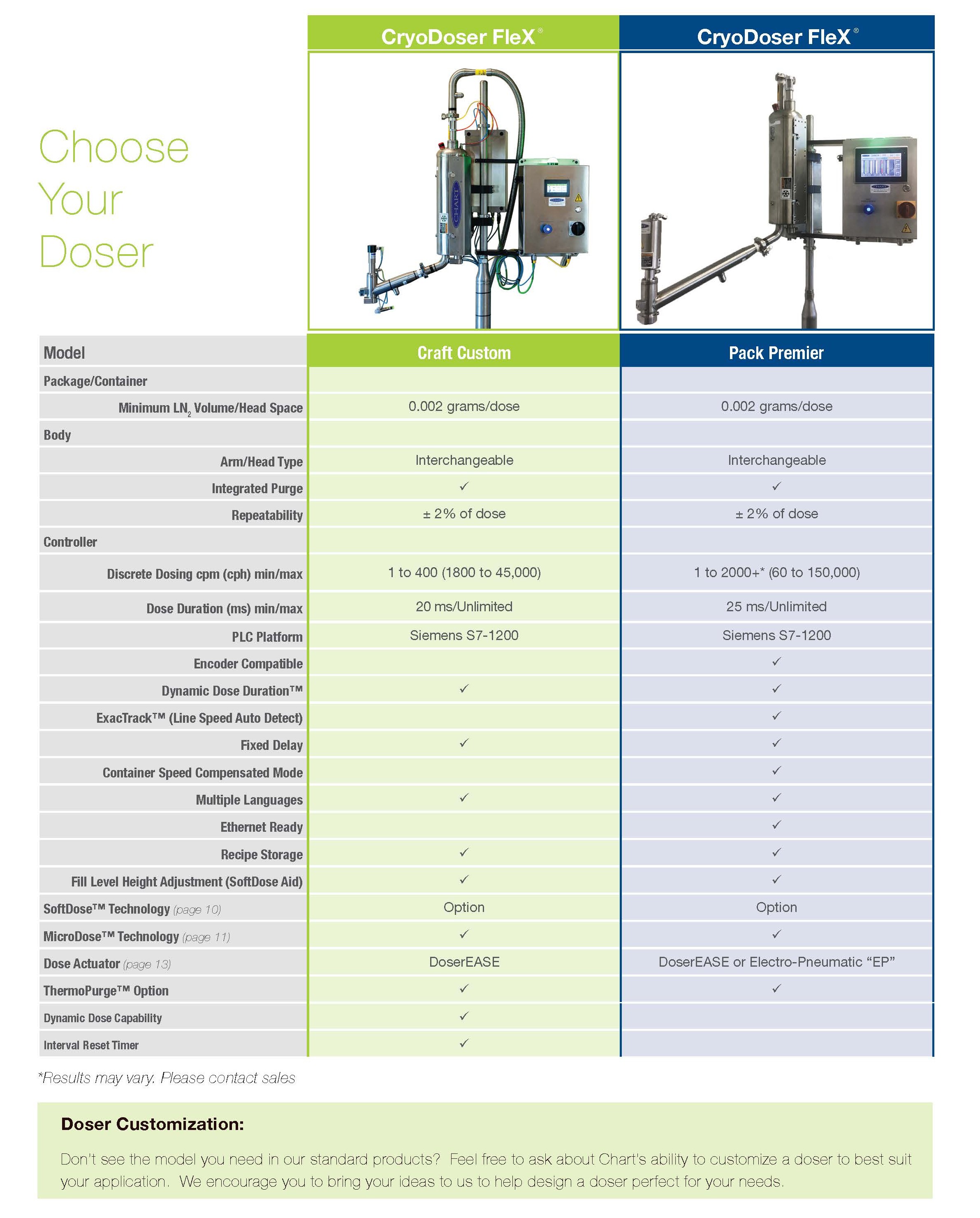

Choose between Craft Custom for small to medium production lines or Pack Premier for high-speed operations

Craft Custom

For craft and medium production

- Dynamic Dose™ up to 16 containers

- Interval Reset Timer

- Recipe Storage

- DoserEASE Actuator

Pack Premier

For high-speed production

- ExacTrack™ Line Speed Auto Detect

- Electro-Pneumatic "EP" or DoserEASE

- Container Speed Compensated Mode

- Ethernet Ready

- Multiple Languages

Key Features

Compact Size

Enables installation in limited spaces without compromising performance

Interchangeable Arm/Head

Adapt to various container sizes and production requirements

Integrated Purge

Automatic system purging reduces maintenance time

SoftDose™ Technology

Proven technology for hot fill, powder, and granular applications

MicroDose™ Standard

Controller function allows precise dosing pressure adjustments

ExacTrack™ (Pack Premier)

With Electro-Pneumatic Head, achieve supreme accuracy with 0.1 ms increments

Technical Specifications

Controller Specifications

Body & Arm Specifications

Key Benefits

Lightweight PET

Reduce container weight for cost and environmental savings

Glass to PET Transition

Eliminate glass safety hazards and reduce container weight

Container Rigidity

Maintain shape even with lighter weight containers

Eliminate Paneling

Increase internal pressure to offset paneling issues

Oxygen Reduction

Create an inert environment to preserve product freshness

Extend Shelf Life

Minimize oxygen levels without preservatives

Ease of Labeling

Consistent rigidity creates efficient labeling process

Reduce N₂ Consumption

Measurable and repeatable liquid doses save nitrogen

Maximize Storage Space

Increased stackability utilizes less warehouse square footage

Ready to Optimize Your Production?

Contact our team to learn more about the CryoDoser FleX system and discover which controller option is right for your production line