LN2 Dosing Systems

Automated liquid nitrogen dosing systems for preservation, pressurization, and freezing in packaging applications. One drop at a time, reducing waste and adding value.

Preservation

Precise LN2 dosing pushes oxygen out of containers, extending shelf life by up to 26% and reducing headspace oxygen by 90-95%.

- Extended shelf life for beverages and oils

- Efficient nitrogen consumption

Pressurization

LN2 vaporizes to create internal pressure, allowing lighter packaging materials and reducing costs by over $2.6M annually per line.

- 9g reduction in PET bottle weight

- Eliminates package paneling

Freezing

Surface freezing locks in product integrity before traditional freezing, maintaining flavor and texture for premium products.

- Maintains product integrity

- Enhanced flavor and texture

Our Product Models

Choose the perfect dosing system for your production needs

CryoDoser FleX® Selection Guide

| Feature | Craft Custom | Pack Premier |

|---|---|---|

| Package/Container | ||

| Minimum LN₂ Volume/Head Space | 0.002 grams/dose | 0.002 grams/dose |

| Body | ||

| Arm/Head Type | Interchangeable | Interchangeable |

| Integrated Purge | ||

| Repeatability | ± 2% of dose | ± 1% of dose |

| Controller | ||

| Discrete Dosing cpm (cph) min/max | 1 to 400 (1,800 to 45,000) | 1 to 2000+* (60 to 150,000) |

| Dose Duration (ms) min/max | 20 ms/Unlimited | 25 ms/Unlimited |

| PLC Platform | Siemens S7-1200 | Siemens S7-1200 |

| Encoder Compatible | ||

| Dynamic Dose Duration™ | ||

| ExacTrack™ (Line Speed Auto Detect) | ||

| Fixed Delay | ||

| Container Speed Compensated Mode | ||

| Multiple Languages | ||

| Ethernet Ready | ||

| Recipe Storage | ||

| Fill Level Height Adjustment (SoftDose Aid) | ||

| SoftDose™ Technology | Option | Option |

| MicroDose™ Technology | ||

| Dose Actuator | DoserEASE | DoserEASE or Electro-Pneumatic "EP" |

| ThermoPurge™ Option | ||

| Dynamic Dose Capability | ||

| Interval Reset Timer | ||

Applications

Chart's nitrogen dosing systems serve diverse industries with precision and reliability

Beverages

- Beer

- Wine

- Juices

- Energy Drinks

- Bottled Water

Food Products

- Condiments

- Vinegar

- Oils

- Sauces

- Dressings

Dairy

- Milk Products

- Yogurt

- Cream

- Cheese

- Ice Cream

Industrial

- Automotive Oil

- Chemicals

- Pharmaceuticals

- Cosmetics

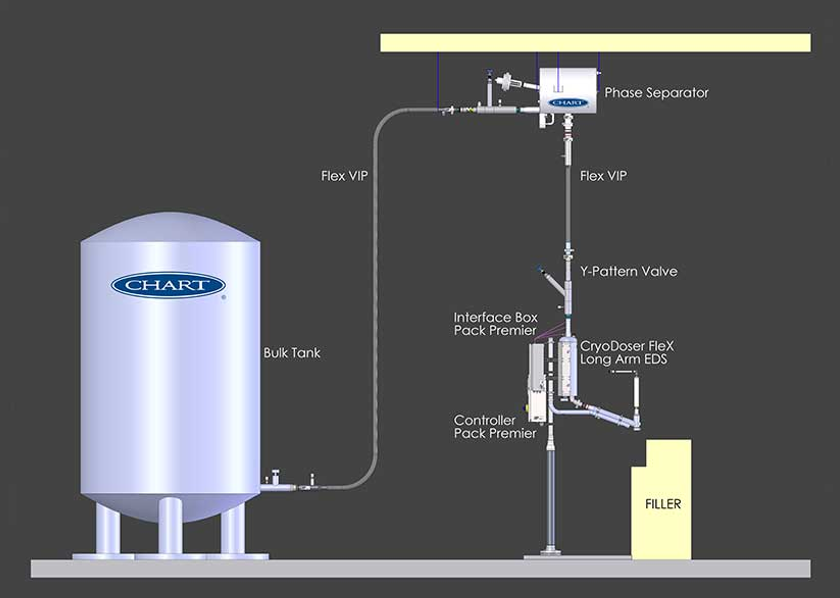

Turnkey Cryogenic Systems: Engineered for Optimal Performance

Complete, custom-engineered solutions for cryogenic storage and vaporization

A Turnkey System, or Engineered Solution, represents a custom, application-focused approach to complete cryogenic storage and vaporization. Designed to be a more efficient, reliable, cost-effective, scalable, and safe alternative to traditional high-pressure gas storage, these comprehensive packages utilize core cryogenic products as the basis of design.

The full scope includes all necessary components such as cryogenic storage tanks, high-efficiency vaporizers, Vacuum Insulated Pipework, advanced control systems, valves, and heaters. By choosing this single-source accountability approach, you gain systems engineered specifically to match your project requirements, ensuring the highest performance and maximum return on investment capital from initial design through installation, post-installation service, and full lifecycle support.

Complete Integration

All components designed to work seamlessly together

Custom Engineering

Tailored to your specific application needs

Single-Source Accountability

One partner for design, installation, and support

Lifecycle Support

Comprehensive service from start to finish

Complete System Integration

Efficiency & Reliability

Optimized system design reduces operational costs while ensuring consistent, reliable performance across all production conditions.

Cost-Effective Solution

Lower total cost of ownership compared to traditional high-pressure gas systems with reduced maintenance and operational expenses.

Safety & Scalability

Enhanced safety features with built-in redundancy and scalable design that grows with your production needs and future expansion.

Why Choose Chart LN2 Dosing?

Precision Dosing

Automated systems deliver exact doses with minimal waste, ensuring consistent quality across production runs.

Cost Savings

Reduce packaging material costs, extend shelf life, and minimize product waste for significant ROI.

Easy Integration

Seamlessly integrates with existing production lines with minimal downtime and training required.

Sustainability

Lighter packaging reduces transportation costs and environmental impact while maintaining product quality.

Ready to Optimize Your Production Line?

Contact Cryotools today to learn how Chart's LN2 dosing systems can reduce costs and improve product quality.

Get in Touch